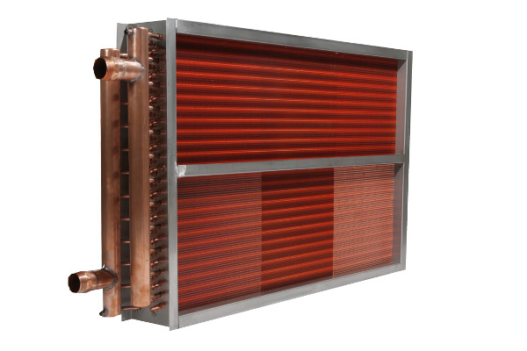

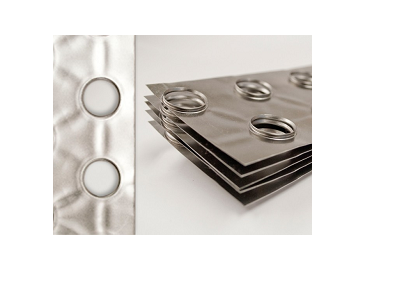

FINS

Optional surface (fins) will be of the plate-blade configuration utilizing aluminum or copper, with kick the bucket framed collars. Balance configuration to be level, waffle, or sine-wave in a stunned cylinder example to meet execution prerequisites. Collars will hold blade separating at determined thickness, and spread the whole cylinder surface. Blades are to be liberated from oils and oxidation.

TUBES

Consistent copper tubes will be precisely ventured into plate aluminum or copper blades, Phenolic Coated Aluminum balances to frame a never-ending bond among essential and auxiliary surfaces. Cylinders are to be precisely ventured into blades (auxiliary surface) for most extreme warmth move.

HEADERS

Headers (manifolds), whenever required, will be developed of a base .060″ divider consistent copper. With copper end tops are brazed within the headers, All loops will be given 1/4″ vents and depletes.

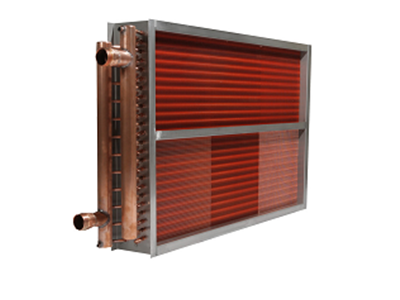

CASING

Coil casing material will be stirred steel at a 16 measure least. Heavier material, hardened steel, housings are accessible as required.

Halfway backings are required each 42″ of finned length and will be dashed to top and base packaging channels. Curl housings on top and base of loops are to have twofold rib development, taking into account vertical stacking of curls.

Schonluft Professional team to be measured the coil dimension and match exact replacement of all major OEM manufactured coils

We also understand time critical projects require quick turnaround. Our expedited production program allows us to offer coil delivery as early as possible